Injection water installation

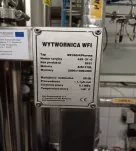

Ready-to-Use WFI System for Pharma and Labs

- Watch the product:

- Add feedback:

-

Availability:

Exists

(1 szt.)

Exists

(1 szt.)

-

| Year of production: | 2021 |

| Industry: | Pharma, Household chemicals, Beauty |

| Product form: | Liquids |

| In our showroom: | No |

| Appraiser's valuation: | Yes |

| Technical Condition: | A - new or mint with low machine hours |

We offer a complete Water for Injection (WFI) system, manufactured in 2021, fully constructed from high-quality AISI 316L stainless steel, designed for pharmaceutical, biotechnology, and medical applications. The system is lightly used and in excellent technical condition – practically like new.

This WFI system meets strict requirements for high-purity process water and is suitable for GMP-regulated environments, where reliability, sterility, and full technical documentation are essential.

Scope of Supply – Complete WFI Package:

- WFI storage tank for safe and hygienic water storage

- TOC (Total Organic Carbon) control, ensuring compliance with pharmaceutical water quality requirements

- Heat exchanger, enabling precise temperature control and thermal management of the process water

- Circulation pump, guaranteeing continuous flow, system stability, and microbiological safety

Thanks to the complete package, the system is ready for immediate implementation without additional investment in key components.

Technical Specifications:

-

Dimensions: 2200 × 1000 × 500 mm

-

Year of manufacture: 2021

-

Material: AISI 316L stainless steel

-

Capacity: 60 l/h

-

Conductivity: < 1.1 µS/cm

-

Operating pressure: 0.7 MPa

-

Operating temperature: up to 140°C

Information about Process Water:

High Purity Water (HPW) is mainly used for pharmaceutical production. Its production is based on double reverse osmosis processes, allowing water with conductivity 1–3 µS/cm to be obtained.

Water for Injection (WFI) is specially purified water intended for injectable solutions for patients. Its very high level of purity is required to meet strict pharmaceutical manufacturing standards, ensuring safety, sterility, and GMP compliance.

Applications of the WFI System:

-

pharmaceutical production

-

biotechnology industry

-

medical facilities and laboratories

-

preparation of injectable solutions

-

cleaning and sterilization of equipment (CIP / SIP)

-

aseptic production lines and processes requiring high-purity water

Benefits for the Customer:

-

Reliable supply of Water for Injection and High Purity Water meeting strict quality standards

-

Process safety and GMP compliance for pharmaceutical production

-

High microbiological and chemical purity of water

-

Stable and repeatable parameters, essential for drug and medical product manufacturing

-

Time and cost savings, thanks to a fully integrated system

-

Fast start-up in existing or new production lines

Why Choose This WFI System?

-

modern unit manufactured in 2021

-

high-quality AISI 316L stainless steel construction

-

excellent technical condition

-

full technical and quality documentation included

-

complete WFI system with tank and steam generator

-

cost-effective alternative to a brand-new installation

-

-

Water for Injection (WFI) System 2021 – Like New!

-

Complete WFI Package with Steam Generator and Tank

-

High Purity Water (HPW) and WFI – Pharmaceutical System

-

Ready-to-Use WFI System for Pharma and Labs

-

WFI 60 l/h – High-Quality Water with Full Documentation

-

AISI 316L WFI System – Ideal for Drug Production

-

WFI & HPW System – GMP-Compliant Installation

-

Used WFI System – Efficient and Reliable

-

Pharmaceutical WFI Station – Complete Setup

-

HPW & WFI System for Laboratories and Production

-

Turnkey WFI System – Ready for Immediate Use

-

High-Purity Water System for Injectable Solutions

-

WFI Station with Tank and Steam Generator – 2021

-

Cost-Effective WFI Solution – Like New Condition

-

GMP-Ready Water for Injection System – Complete Installation

-

Ask a question about the product. Our team will be happy to provide a detailed answer to your inquiry.

Polish

Polish