Complete line for sorting, counting, and sealing - NEW

Countec production line – 2021

- Watch the product:

- Add feedback:

- Manufacturer: Countec

-

Availability:

Exists

(1 szt.)

Exists

(1 szt.)

-

| Year of production: | 2021 |

| Industry: | Pharma, Suplements |

| Product form: | Capsules, Tablets |

| Packaging types: | Bottles |

| In our showroom: | Yes |

| Appraiser's valuation: | Yes |

| Technical Condition: | A - new or mint with low machine hours |

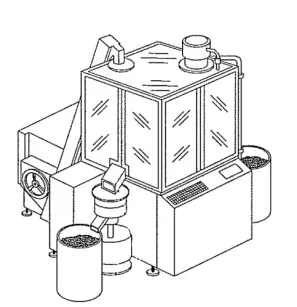

A complete COUNTEC bottle filling and capping line, manufactured in 2021.

The line has never been used.

The set includes three devices:

- UA-100 automatic bottle orienter,

- DMC4CW tablet counter,

- OC-60 semi-automatic press-on capper.

The whole set is an integrated solution for the preparation, dosing, and closing of containers in pharmaceutical processes.

1. COUNTEC UA-100 automatic bottle orientator

A modern automatic orienting and blowing machine designed for positioning, cleaning, and feeding empty bottles onto the production line.

The device handles containers with a diameter of 30-100 mm and a height of 40-180 mm, achieving a capacity of up to 100 bottles per minute.

Equipped with a dual cleaning system (filtered, ionized air and vacuum suction) and a pharmaceutical air filter, it ensures a high standard of hygiene.

The fully adjustable turntable eliminates the need to replace parts when changing formats.

The automatic rejection system removes overturned or incorrectly positioned bottles.

Control is via an HMI/PLC panel, which allows for quick configuration and intuitive operation.

2. COUNTEC DMC4CW tablet counter

A precise electronic counter with four independent dosing channels, equipped with infrared sensors that guarantee 100% counting accuracy.

Ideal for small and medium production runs, it offers a throughput of up to 1,500 tablets per minute (for tablets with a diameter of approx. 8 mm).

The system k

3. COUNTEC OC-60 semi-automatic capping machine

A robust semi-automatic press-on capping machine designed for closing bottles with press-on caps.

Capacity up to 60 bottles/min, bottle size range: diameter 30–100 mm, height 40–200 mm.

The device uses a mechanical pressure system, ensuring repeatable and tight closures.

Easy to use, designed for semi-automatic operation – the operator manually places the bottles under the head, which then presses the cap on.

A control panel with buttons, low energy consumption (0.5 kW), and compliance with GMP standards make it the perfect addition to a compact line.

Key advantages of the COUNTEC line (2021):

- Complete set: orientation, counting, closing

- Full compliance with GMP requirements and high hygiene standards

- Intuitive PLC/HMI control

- No need to replace format parts in the orientator

- Precise counting and smooth operation

- Compact design – ideal for small and medium production runs

- Year of manufacture 2021, new / ready for operation

Ask a question about the product. Our team will be happy to provide a detailed answer to your inquiry.

Polish

Polish