15L homogenizing and batch mixer (2 pcs.)

Urliński mixers - 15L batch mixer and 15L homogenizing mixer

- Watch the product:

- Add feedback:

- Manufacturer: Urliński

-

Availability:

Exists

(2 szt.)

Exists

(2 szt.)

-

| Year of production: | 2023 |

| Industry: | Inne, Pharma, Suplements, Household chemicals, Beauty |

| Product form: | Liquids |

| In our showroom: | No |

| Appraiser's valuation: | No |

| Technical Condition: | A - new or mint with low machine hours |

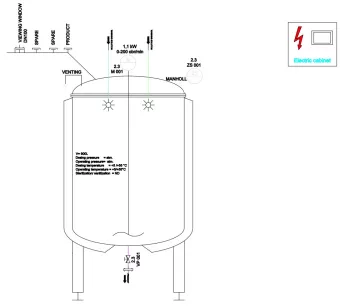

Urliński MZUTL 15 Batch Mixer

Product description:

The MZUTL 15 is a high-class batch mixer manufactured by Urliński, designed for precise mixing of various substances in production processes in the cosmetics, pharmaceutical, chemical, and food industries. Thanks to its robust construction and modern technology, the device ensures excellent process repeatability and high quality of the mixtures obtained.

Main features:

- Total mixing chamber capacity 26 l, working capacity 15 l, minimum load - 5 l.

- Contact parts made of 1.4301 (304) stainless steel.

- The mixer has a top-mounted anchor mixer driven by a 0.55 kW electric motor, 1400 rpm.

- The working speed of the anchor mixer is adjustable in the range of 32-160 rpm.

- The mixer has a comb homogenizer mounted under the chamber, driven directly by a 7.5 kW electric motor, 2885 rpm.

- The working speed is adjustable in the range of 1430 - 6630 rpm.

- The mixing chamber is designed to operate at temperatures ranging from 5 to 99°C.

- Operating pressure ranges from -0.2 to 0.8 bar.

- The heating jacket is made of steel and is designed to operate at temperatures ranging from 5 to 120°C.

- Operating pressure is 3.6 bar.

- The mixing chamber and homogenizer are connected by a bypass pipe. The mixer has a local control panel and a heating tank with heaters (7 kW).

Application:

Ideal for mixing emulsions, creams, gels, suspensions, and other products requiring precise ingredient dosing and process control.

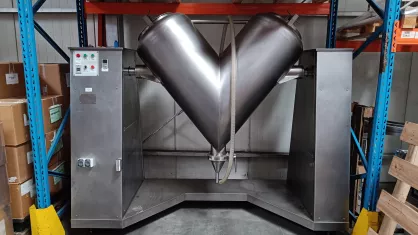

Urliński MZUT-EMBF 15 Homogenizing Mixer

Product description:

The MZUT-EMBF 15 model is an advanced homogenizing mixer designed for the production of demanding, homogeneous emulsions and suspensions. Thanks to the built-in EMBF bottom homogenizer, the device ensures exceptionally fine dispersion of the dispersed phase, which translates into the smoothness and stability of the final product.

Main features:

- Total mixing chamber capacity 26 l, working capacity 15 l, minimum batch size - 5 l.

- Contact parts made of 1.4301 (304) stainless steel.

- The mixer has a knife emulsifier mounted at the bottom, driven directly by a 5.5 kW motor, 2890 rpm.

- Working speed adjustable in the range of 1500-5500 rpm.

- The mixing chamber is designed to operate at temperatures between 5-90°C.

- Working pressure - 0 bar.

- The stainless steel heating jacket is designed to operate at temperatures ranging from 25-120°C.

- Jacket pressure up to 4 bar.

- The mixer has a local control panel and a heating tank with heaters (7 kW).

- The product can be heated and cooled.

- Digital control with cycle programming function.

Application:

Dedicated to the production of high-quality cosmetics (creams, lotions, milks), pharmaceutical ointments, sauces, pastes, and emulsions requiring exceptional stability and homogeneity.

Ask a question about the product. Our team will be happy to provide a detailed answer to your inquiry.

Polish

Polish