Why is it worth buying used production lines and machines from Poland?

Poland has become one of the most attractive locations in Europe for purchasing used machinery and production lines for the pharmaceutical, cosmetics, and dietary supplement industries. More and more international companies are discovering that investing in equipment from Poland offers a way to significantly reduce costs, start production quickly, and ensure European-level quality.

Efficiency, quality, and cost advantage in one place

In recent years, the European market for pharmaceuticals, dietary supplements, and cosmetics manufacturing has faced a growing challenge: how to expand production capacity while maintaining profitability amid rising cost and regulatory pressure.

The answer that our industry is increasingly discovering is: Poland.

For several years now, mid-sized European manufacturers have been observing the dynamic growth of Poland’s production technology sector — and the expanding opportunities to acquire used, fully functional production lines and individual machines under highly attractive conditions.

1. Poland – Europe’s center of process technology

For decades, Poland has been a strong industrial hub in pharmaceuticals, cosmetics, and household chemistry. Across the country, many manufacturing facilities are modernizing their operations, often replacing fully functional lines with new, more automated systems.

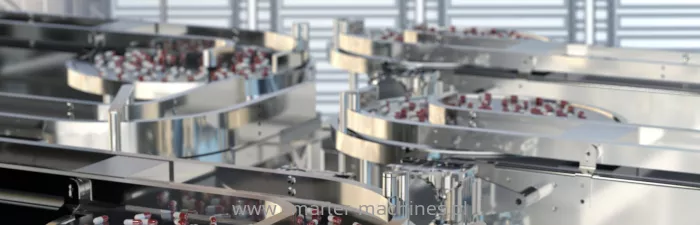

As a result, the secondary market offers a wide range of machines from renowned manufacturers — Fette, Glatt, IMA, Bosch, Marchesini, Kaps-All, Uhlmann, Romaco, and Polish brands such as Unilogo, Ulinski, KERT — all in excellent technical condition.

Unlike in many other countries, this equipment in Poland is typically maintained to a high GMP standard, complete with full technical documentation and service history.

2. Attractive price-to-quality ratio

Purchasing used machines in Poland can result in 40–70% savings compared to new equipment of the same class.

Moreover, many companies offer comprehensive preparation of the machines for reinstallation abroad — including dismantling, cleaning, FAT testing, and adaptation to local power and automation standards.

In practice, this means you can acquire a complete production line for tableting, blister packaging, liquid filling, or cream processing at a fraction of the cost of a new system — without compromising on quality.

3. Technical support and know-how

Polish companies specializing in machinery trade and refurbishment often provide full support for foreign installations, including:

-

preparation of technical and installation plans,

-

on-site assembly and commissioning,

-

operator training,

-

IQ/OQ/PQ validation according to GMP standards.

Thus, purchasing equipment in Poland is not merely a transaction — it’s a technological partnership, enabling rapid production startup with minimal risk.

4. Compliance with European regulations

Most used machines from Polish facilities already meet EU Machinery Directive requirements, carry CE marking, and include material certificates, greatly simplifying the import and registration process in other EU member states.

5. Sustainability and circular economy

In the era of ESG and the green transition, purchasing used equipment from Poland is not only an economic decision — it’s an ecological one.

Utilizing existing technological assets reduces carbon footprint, limits industrial waste, and extends equipment lifecycle — all while maintaining the high quality standards of the pharmaceutical industry.

6. Speed of implementation

While ordering new machines often involves 12–18 months of lead time, acquiring used equipment from the Polish secondary market can enable production startup within a few weeks of the investment decision.

In today’s rapidly changing pharmaceutical market, this is an advantage that cannot be overstated.

Conclusion

Purchasing used production equipment from Poland is a strategic choice for European manufacturers seeking to combine cost efficiency with high quality and regulatory compliance.

The Polish market offers a unique blend of technical maturity, engineering expertise, and readily available GMP-standard equipment.

For many producers across Europe, Poland has become the natural source for acquiring machinery and production lines to modernize and expand their manufacturing infrastructure.

Looking for a bargain?

Check out our offer of refurbished production lines, machines, and related services.

Polish

Polish