How to become a dietary supplement manufacturer?

Poles love dietary supplements — numerous studies confirm it. It’s no surprise, then, that many people are wondering how to develop their own formula and enter this rapidly growing market. So, what steps need to be taken to introduce a dietary supplement to the Polish market?

Poles Are Increasingly Turning to Dietary Supplements and Investing in Their Health

Poles are actively looking for ways to improve their health and are increasingly turning to supplements that support immunity, help reduce stress, and improve sleep quality and cognitive function. A survey conducted in July 2024 by PMR Market Experts showed that four in ten respondents take supplements daily, and 35% use several types simultaneously. Meanwhile, in a 2022 study by Adamed, more than half of participants (55.6%) admitted that they had taken dietary supplements and/or over-the-counter preparations in the past year. Women were significantly more likely to do so than men (62.6% and 46.9%, respectively).

Sales trends remain strong and, according to experts, will continue to grow. It is estimated that the value of the dietary supplements market in Poland could reach as much as PLN 7 billion in 2024. Let’s take a closer look at the production, distribution, and legal requirements governing this industry.

Who Can Produce and Sell Dietary Supplements?

Under current regulations, dietary supplements are classified as food products rather than medicines. This means they are subject to the Food and Nutrition Safety Act and must comply with the requirements of the Chief Sanitary Inspector (GIS). Below are the main requirements for supplement manufacturers:

-

At least 14 days before starting the planned activity, you must submit an application for registration or approval of the facility to the Sanitary Inspection (Sanepid).

-

Any dietary supplement placed on the market must be notified to the appropriate authority, which verifies whether the product’s composition, form, and labeling meet legal requirements. If you are introducing a new supplement not previously available on the market, you must submit a notification to the Chief Sanitary Inspectorate (GIS). The notification is submitted electronically via the GIS Electronic Notification System.

-

The manufacturing facility must meet sanitary and hygiene requirements applicable to food production. Implementing approved quality and safety systems such as HACCP and Good Hygiene Practice (GHP) is essential, and many companies also adopt Good Manufacturing Practice (GMP) standards for additional quality control.

-

A dietary supplement may contain only ingredients permitted for use in this category, in the appropriate form and amount. The relevant guidelines are set out in the Regulation of the Minister of Health of October 9, 2007, on the composition and labeling of dietary supplements, and the Food and Nutrition Safety Act.

-

The product label must include key information such as the product category (“dietary supplement”), name, ingredient list, indications for use, dosage, warnings, contraindications, and storage instructions (“keep out of reach of children”). It is prohibited to suggest that the supplement cures diseases — it is a food product, not a drug.

-

Regulations also require detailed production documentation, including procedures, raw material specifications and certificates, production reports, and quality control results.

How to Manufacture Your Own Dietary Supplement

The production of dietary supplements is a complex process involving many stages and requiring considerable expertise and experience. If you do not have your own production line or the necessary human resources, the simplest solution is to use a contract manufacturing service.

Contract manufacturing allows you to save time and money — the service provider handles the key stages of production, including formulation development, raw material procurement, processing, packaging, and labeling. Final product testing can also be outsourced to an external laboratory, enabling you to compile the documentation confirming the quality of your supplements.

The importance of quality is evident: over 50% of respondents in the PMR Market Experts survey declared a willingness to buy premium products, while 28% focused primarily on price, and 25% preferred supplements offered in promotional deals. Each year, approximately 20,000 new products are registered in Poland, and around 45,000 companies operate in the supplement sector (some focusing solely on distribution).

This makes the business increasingly competitive, forcing companies to continually adapt their production and marketing strategies to meet rising consumer expectations. Expert consulting on product formulation, ingredient selection to ensure high quality and regulatory compliance, and investment in flexible production lines enabling short-run manufacturing are now key success factors.

When choosing a business partner, assess not only the scope of contract manufacturing services offered but also whether their production lines use modern optimization techniques — such as reduced changeover times, quick and flexible format adjustments, and automated process monitoring to minimize production errors.

In-House Production

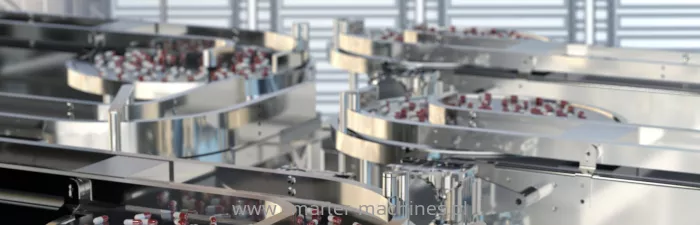

Contract manufacturing is a convenient and cost-effective solution. However, if you have the right facilities, staff, ready formulas, and want to handle production or packaging yourself, we encourage you to explore our range of new and used production machines.

In our used machinery store, you will find a wide selection of:

- Complete production lines

- Process equipment

- Packaging machines

- Laboratory and auxiliary equipment

All of which will help you quickly join the ranks of dietary supplement manufacturers.

If you’re planning to set up a new production line,

check out our range of new lines, machines, and services.

We will find, relocate, and upgrade a production line from one of our clients just for you — or design, deliver, install, and commission an entirely new one.

Polish

Polish